Methods of venting plumbing fixtures and traps in the 2021 International Plumbing Code

The International Code Council is proud to distribute a helpful tool — Methods of Venting Plumbing Fixtures and Traps in the 2021 International Plumbing Code: Installation, Flexibility and Opportunity for Savings — to help expand your knowledge of the International Plumbing Code (IPC). The various approaches to venting that are permitted in the 2021 IPC are described in this handy reference tool authored by Lee Clifton, senior director of PMG resources at the Code Council. You will find that these venting provisions offer the installer and designer different paths to achieving an adequately vented system, which could result in cost savings along with ease of installation in different types of construction.

The International Code Council is proud to distribute a helpful tool — Methods of Venting Plumbing Fixtures and Traps in the 2021 International Plumbing Code: Installation, Flexibility and Opportunity for Savings — to help expand your knowledge of the International Plumbing Code (IPC). The various approaches to venting that are permitted in the 2021 IPC are described in this handy reference tool authored by Lee Clifton, senior director of PMG resources at the Code Council. You will find that these venting provisions offer the installer and designer different paths to achieving an adequately vented system, which could result in cost savings along with ease of installation in different types of construction.

Chapter 9 of the IPC describes a variety of methods to vent plumbing fixtures and traps. The methods have been laboratory tested to determine sizing and installation requirements that provide proper venting to a drainage system. The venting methods have also been field-tested, establishing a long history of satisfactory service.

In this first of a four-part series of articles, the various approaches to venting that are permitted in the 2021 IPC are presented. To help keep in mind that “stack vents” and “vent stacks” are distinct, a short glossary of definitions is provided as well.

Chapter 9 of the International Plumbing Code (IPC) describes a variety of methods to vent plumbing fixtures and traps. The methods have been laboratory tested to determine sizing and installation requirements that provide proper venting to a drainage system. The venting methods have also been field-tested, establishing a long history of satisfactory service.

In this publication, we will present the various approaches to venting that are permitted in the 2021 IPC. You will find that these venting provisions offer the installer and designer different paths to achieving an adequately vented system, which could result in cost savings along with ease of installation in different types of construction.

Three specific venting methods

Section 901.2.1 of the IPC establishes that traps and trapped fixtures shall be vented in accordance with one of the venting methods specified in this Chapter. Section 904.1 requires the vent system serving each building drain to have at least one vent pipe that extends to the outdoors.

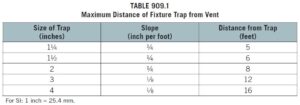

The most widely used method is commonly referred to as a conventional venting system. Table 909.1 (below) provides the maximum distance allowed for a vent in relation to the trap. A fixture vent connected in this manner is called an individual vent. These individual vents are sized according to Section 906.2. Here we find that the vent must be at least one-half the diameter of the drain served, but in no case less than 1¼ inches in diameter.

Remember, the vent size is not based on the trap or fixture drain (trap arm), but the drain size that continues downstream from the point where the vent and fixture drain connect. The drain size is determined by the fixture unit load in accordance with Tables 709.1, 709.2, 710.1(1), and 710.1(2) in the IPC. Hence, if the drain size is 4 inches (102 mm), a 2-inch (51 mm) vent is required. A 3-inch (76 mm) drain would require a 1½-inch (38 mm) vent. A 2-inch (51 mm), 1½-inch or 1¼-inch (38 or 31.8 mm) drain would require a minimum 1¼-inch (31.8 mm) vent, this being the minimum size allowed.

Section 905.5 allows individual vents to merge with each other, as long as the connection is made at least 6 inches above the flood-level rim of the highest fixture served. Sizing of the vents as they connect is again based only on the required size of the drain being served. Section 906.2 requires that vents exceeding 40 feet (1016 mm) in developed length shall be increased by one nominal pipe size for the entire developed length of the vent pipe.

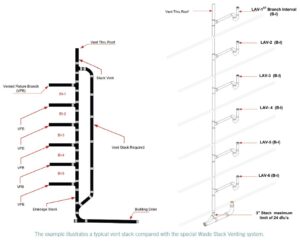

It is important to know that Section 904.2 states a vent stack shall be required for every drainage stack that has five branch intervals or more. If the drainage stack is less than five branch intervals in height, a vent stack is not required because the pressure in the drainage stack is not likely to create a pressure differential at the trap seals in excess of 1 inch (25.4 mm) of water column. When required, vent stacks are to be dry and are required to connect at or near the base of the stack served to act as a relief vent for the pressures that develop in the lowest portions of the stacks.

The exception in Section 904.2 wisely eliminates an unnecessary vent to a system that already has adequate fresh air exchange assurance. Waste stack vented systems, as covered in Section 913, are already oversized to provide for adequate venting without the need for additional venting.

The code only requires stack vents for drainage stacks in Section 913.3 because the minimum required venting of each fixture has been accomplished when the system complies with the venting methods outlined in Chapter 9. A stack vent is typically used as a collection point for vent pipes so that a single roof penetration can be made.

Keep in mind that “stack vents” and “vent stacks” are distinct. See definitions in the next section.

Definitions

Branch Vent. A vent connecting one or more individual vents with a vent stack or stack vent.

Circuit Vent. A vent that connects to a horizontal drainage branch and vents two traps to no more than eight traps or trapped fixtures connected into a battery.

Combination Waste and Vent System. A specially designed system of waste piping embodying the horizontal wet venting of one or more sinks or floor drains by means of a common waste and vent pipe adequately sized to provide free movement of air above the flow line of the drain.

Common Vent. A vent connecting at the junction of two fixture drains or to a fixture branch and serving as a vent for both fixtures.

Individual Vent. A pipe installed to vent a fixture trap and that connects with the vent system above the fixture served or terminates in the open air.

Stack Vent. The extension of a soil or waste stack above the highest horizontal drain connected to the stack.

Stack Venting. A method of venting a fixture or fixtures through the soil or waste stack.

Vent Stack. A vertical vent pipe installed primarily for the purpose of providing circulation of air to and from any part of the drainage system.

The developed length of individual, branch, circuit, and relief vents shall be measured from the farthest point of vent connection to the drainage system to the point of connection to the vent stack, stack vent, or termination outside of the building.

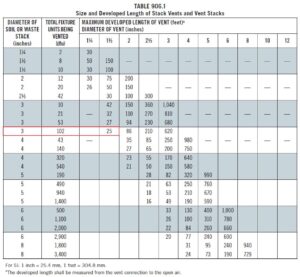

There are important criteria to remember when sizing a conventional venting system composed of individual fixture vents, vent stacks, and stack vents. The minimum size of an individual vent is one-half the required drain size, whereas the minimum size of the vent stacks and stack vents is one-half the size of the drain served.

The sizing criteria for stack vents and vent stacks are based on three variables:

- The developed length of the vent.

- The size of the stack served by the vent.

- The total drainage fixture unit (DFU) connected to the stack.

Example A:

A 3-inch (76 mm) soil stack with a stack vent serving as the required vent extension to the outdoors, connecting to a 3-inch (76 mm) building drain, must have at least a 1½-inch (38 mm) stack vent [maximum of 102 fixture units served and a maximum 25-foot (7620 mm) developed length] in accordance with Section 906.1 and Table 906.1. This 1½-inch (38 mm) stack vent is the minimum size required to comply with this section because it is at least one-half the size of the building drain.