Hazardous materials and building occupancy classification: Six key concepts to master

Unlike other hazardous materials regulations, fire and building codes specify a building’s design and construction to prevent and mitigate fires and emergencies involving hazardous materials. The occupancy classification establishes fire and life safety features needed to protect building occupants, firefighters, and emergency responders, so it’s essential to get it right.

Unlike other hazardous materials regulations, fire and building codes specify a building’s design and construction to prevent and mitigate fires and emergencies involving hazardous materials. The occupancy classification establishes fire and life safety features needed to protect building occupants, firefighters, and emergency responders, so it’s essential to get it right.

There are six concepts every code official should master to verify the occupancy classification of buildings containing hazardous materials successfully.

The process

The process to determine whether a high-hazard (Group H) occupancy is needed is the same whether you are evaluating hazardous materials in wholesale/retail sales occupancies, higher education laboratory suites, or any other occupancy. What differs between these scenarios is the number of control areas and quantities of hazardous materials allowed before a Group H classification applies.

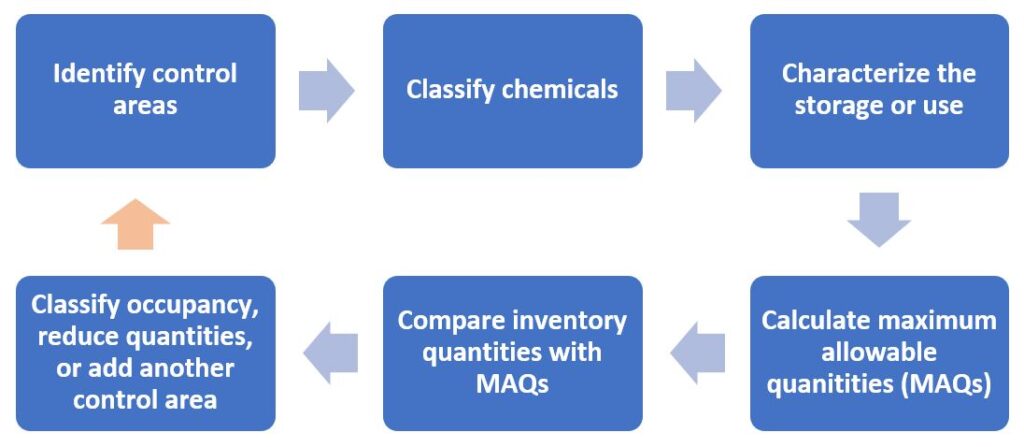

Process steps:

- identify the control area(s)

- classify the hazardous materials in the control area

- characterize and determine the hazmat quantities in each condition (i.e., storage, closed-use and open-use)

- calculate the maximum allowable quantities (MAQs) for relevant hazard classes

- evaluate whether inventory quantities exceed the MAQs

- decide whether to classify the occupancy, reduce quantities or create additional control areas

The control area

Control areas are isolated compartments in a building where reasonable quantities of hazardous materials can be stored or used without causing the building to be classified as a high-hazard occupancy. Compartmentalization is a fundamental fire protection strategy intended to limit the spread of fire and smoke long enough for occupants to exit the building safely or, in some cases, “defend in place.”

Although the code prescribes the number of control areas allowed on each building story and the fire-resistive rating of the walls and floors if more than one control area exists, code officials are not responsible for establishing control areas. That’s left for facility operators and designers. It can be as simple as designating the entire building as one control area or as complex as control areas that span multiple floor levels. Code officials only need to verify that the established control areas are compliant.

Further, control areas are not required to be static. The building area that comprises a control area can be modified as frequently as needed, provided it still meets all the control area conditions.

Classifying the hazards

Accurately classifying the hazards presented by each material is crucial in determining if a high-hazard occupancy is needed and the appropriate high-hazard occupancy Group. It can also be tedious, as many substances have multiple hazards, and proper classification requires identifying all of them. One of the most challenging tasks code officials face is determining whether inventory chemicals are correctly classified.

Hazardous materials are substances that present a physical or health hazard, including combustible liquids, cryogenic fluids, explosives, flammables, organic peroxides, and oxidizing, pyrophoric, unstable (reactive), water-reactive, toxic, highly toxic, or corrosive materials.

The International Fire Code (IFC) and International Building Code define each hazard category and class based on the severity of the hazard. These definitions have their basis in the Code of Federal Regulations, particularly 29 CFR 1910.1200 (OSHA) and 49 CFR Part 172 (DOT), which manufacturers used to prepare Material Safety Data Sheets before June 1, 2015.

Appendix E of the IFC provides a limited list of examples of typical chemicals in each hazard class. While Safety Data Sheets (SDS) still offer insight into the hazards presented by materials, manufacturers now use the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) to develop SDSs, and GHS definitions and hazard categories do not align with the International Codes (I-Codes).

Similarly, DOT hazard classifications are unique to transportation and provide clues about the hazards but cannot be relied upon to classify materials for occupancy.

Numerous technical references are available to research a material’s chemical and physical properties, but none directly offers classifications based on the I-Codes.

A recently updated online tool, HMEx Assistant, includes a chemical database of more than 3,400 chemicals classified based on the I-Code definitions. It offers code officials an easy way to look up and verify material hazard classes.

Storage and use

When evaluating hazardous material quantities, the amounts in storage and use are considered separately.

Storage involves hazardous materials in closed containers, tanks, cylinders, or similar vessels.

The code characterizes materials in use to be in a closed or open system of vessels, piping, and equipment. To distinguish between these, one should look at whether the system emits vapors during normal operations. Closed use involves a closed vessel or system, and the product, or vapor it emits, is not exposed to the atmosphere during normal operations. Open use consists of a vessel or system that’s continuously open to the atmosphere or exposes product or vapors to the atmosphere during normal operations.

When applying any of these terms, the quantity considered is typically the capacity of each container, not the contents, and the material contained in piping does not generally contribute to the amount.

Maximum allowable quantities

The limited quantity of hazardous materials allowed in a control area is outlined for each hazard class and referred to as the maximum allowable quantity, or MAQ, per control area.

MAQs are amounts considered to represent a reasonable risk or do not present a significant threat without additional controls. Factors that can influence the MAQ are:

- whether an automatic sprinkler system protects the building,

- whether the material is contained in approved cabinets, exhausted enclosures, or gas rooms, and

- the building story, above or below grade plane.

Quantities up to the MAQ are allowed in each hazard class for each physical state and condition (i.e., storage, open-use, closed-use systems). Generally, however, the total amount allowed in storage and use cannot exceed the MAQ for storage.

Beyond the MAQ, consider the additional occupancy-based quantity limits that apply to some hazard classes. When these limits apply, they appear in the material-specific chapters of the IFC.

Occupancy classification

Where inventory quantities exceed the MAQ for one or more hazard classes in a control area and neither reducing quantities nor adding control areas are viable alternatives, a high-hazard occupancy classification is needed. The specific high-hazard occupancy Group(s) are dependent on which hazard class MAQs are exceeded.

For facilities involving hazardous materials, the I-Codes require submission of a Hazardous Materials Inventory Statement (HMIS) that itemizes the hazardous materials, quantities in storage and use and the hazard classes assigned. Code officials need the HMIS to validate materials are correctly classified.

What’s not required, but should be, is a Hazard Class Summary Report that compares the aggregate inventory quantity with the MAQ for each hazard class, physical state, and condition (i.e., storage, closed-use, and open-use). The summary report contains the information needed to confirm the proper high-hazard occupancy group is assigned. Without it, code officials must rely on the design professional’s assessment.

Final words

The role of the code official is to verify that control areas and MAQs are appropriately implemented and maintained and occupancies involving hazardous materials are correctly classified. This verification helps ensure a building has the minimum fire and life safety features needed to control hazards presented by the materials. It requires understanding the key concepts and mandating the submittal of documents that demonstrate compliance and support the assigned occupancy classification.