Strong connections

Building codes and referenced standards are constantly evolving. A three year or longer cycle for development of codes and standards may present challenges to manufacturers’ product development plans. Through the provisions in the International Building Code (IBC) Section 104.11 Alternative materials, design and methods of construction and equipment, however, the ICC Evaluation Service (ICC-ES) keeps pace with innovative product development through a continuous cycle of new Acceptance Criteria (AC) being proposed and revised every year.

In 2015, ICC-ES collaborated with the Deutsches Institut für Bautechnik (DIBt) to develop a new Acceptance Criteria for Load-Bearing Thermal Break Assemblies (LBTBAs) Installed Between Concrete Balconies and Concrete Floors (AC464). ICC-ES AC464 was partially based on a new European Assessment Document (EAD) for LBTBAs, which form a thermal break between concrete balconies and internal concrete floors. Structural load tests, fire resistive assembly tests and engineering analysis were used as the basis for AC464, and allowed for a parallel evaluation to the EAD.

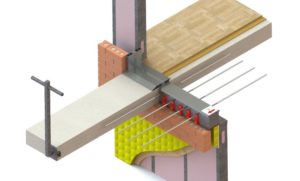

The first ICC-ES evaluation report under AC464 was issued to HALFEN GmbH in ESR-3799. The HALFEN technical team, led by Dr.-Ing. Thorsten Heidolf, implemented a very proactive approach, including structural and fire testing done as part of their European Technical Assessment (ETA). A review of the HALFEN test data and analysis confirmed compliance with ICC-ES AC464 requirements, and qualifying inspections of the HALFEN manufacturing facilities in Europe and the U.S. were successfully completed prior to publication of ESR-3799. The HALFEN Insulated Connection (HIT) is a load bearing connection used as a structural thermal break for concrete to concrete connections such as reinforced concrete floor with reinforced concrete balconies. The HALFEN HIT system is a novel load-bearing connection assembly that utilizes steel reinforcing bars and innovative compression shear bearing units to transmits shear forces, bending moments or a combination of both shear and bending moments. Mineral wool is utilized as both an insulating and a fire protection material providing a minimum two-hour fire rating. Strut and tie models are used to analyze and design the HALFEN HIT structural connections in regards to the concrete failure modes. The technical solution to the complex connection behavior was facilitated by open and frequent communication between HALFEN, ICC-ES and DIBt throughout the review process.

“The combination of ICC-ES’s and DIBt’s technical expertise and communication skills made the development of AC464 and the ESR 3799 approval process very easy and straight forward,” said Dr.-Ing. Heidolf, team manager of Structural Physical Products and Reinforcement Systems at HALFEN. “As a product manufacturer, we appreciate ICC-ES’s cooperation and quick turn-around as ICC-ES reports are a critical component of our marketing and design strategy. During all phases of the process we felt that all parties were working together as a team to accomplish a goal. The advantage for our customers is that the area of application, the design concept and other rules are checked and clearly described by experts.”

In 2017, HALFEN’s HIT Insulated Connection received the first ICC-ES Evaluation Report (ESR 3799) for a structural thermal break system from ICC-ES. HIT allows insulation to run continuously through the balcony increasing the effective R-value of the overall wall system by almost two times compared to an unthermally broken balcony.

ICC-ES and DIBt collaborated to develop AC464 under a Memorandum of Understanding (MOU) between the two product evaluation agencies. The MOU underscores the trust that the agencies have in each other’s technical and quality management processes. Other collaboration projects between ICC-ES and DIBt are currently in the works for different types of building products. “Global markets call for global product assessment solutions. We are happy to cooperate with ICC-ES to provide high quality product evaluations to our industry partners. Aligning American and European technical specifications is a key factor in reducing evaluation costs and times-to-market for our customers,” said DIBt Vice President Dr.-Ing. Karsten Kathage.

“ICC-ES’ cooperation with DIBt was shaped to solve global manufacturers’ conformity assessment challenges,” said William Gould, ICC-ES vice president of External Relations & Client Services. “This partnership works because the two organizations have the same mission, and that is to streamline the global conformity assessment process while helping save lives in the built environment.”

Subsequent revisions to ICC-ES AC464 were approved by the Evaluation Committee in June 2017 in order to address expanded polystyrene (EPS) as a different LBTBA insulating material, in addition to the mineral wool insulation previously approved in 2015. EPS insulating blocks used as part of an LBTBA under ICC-ES AC464 must also comply with the testing and manufacturing quality requirements in ICC-ES Acceptance Criteria for Foam Plastic Insulation (AC12).

The primary purpose of ICC-ES evaluation reports is to provide building code officials with evidence of code compliance in accordance with Section 104.11 of the IBC. The primary benefit of ICC-ES evaluation reports to the manufacturer is to facilitate approval of their products by local building code officials. Evaluation reports, listings and approvals thus indirectly help the manufacturers grow their business through recognition under the IBC. Evaluation reports also provide peace of mind to design professionals that the product has been independently reviewed by an ISO/IEC 17065 accredited conformity assessment body with expertise in evaluating the specific product. A lot of work goes on behind the scenes in development of an AC from the manufacturer, ICC-ES staff and other interested parties including the proponent manufacturer. As part of the ICC-ES evaluation process, surveillance inspections of the product manufacturing are also done for the life of the evaluation report. This ensures continuous compliance of the product with the ICC-ES AC and IBC requirements. “We are very proud to be part of this alliance of evaluation experts, working collaboratively to help reduce any code conformity issues manufacturers may face, in both the United States and Europe,” said ICC-ES President Shahin Moinian, P.E. “Together, we will increase efficiency in product evaluation and testing.”

The collaboration between ICC-ES and DIBt is unique. It has allowed for sharing of manufacturer test data and associated analyses in order to establish compliance with the ICC-ES AC and EAD simultaneously. HALFEN was able to obtain an ESR and ETA under a unified testing and analysis program through the cooperative effort of ICC-ES and DIBt. In the end, the process was very efficient saving both time and money.

Other manufacturers seeking evaluation reports for compliance with the International Codes can work directly with ICC-ES as usual if they intend to market and sell their products in the U.S. If manufacturers also want to obtain an ETA to increase their global market reach, the MOU between ICC-ES and DIBt allows for a collaborative project with both evaluation agencies, streamlining the process for dual certifications in the U.S. and Europe.

Manufacturers interested in applying for an ICC-ES evaluation report may contact Michael Temesvary, P.E., at (800) 423-6587, ext. 3877.