Water Heater Sizing and Location: Code vs. Practicality

This article explores the intersection of code requirements and practical realities, offering insights for inspectors, installers and designers alike.

Water heaters are indispensable to any building plumbing system, yet their sizing and placement are often misunderstood or undervalued. While the International Plumbing Code® (IPC®) offers clear guidance on installation and performance expectations, real-world conditions frequently challenge strict compliance.

This article explores the intersection of code requirements and practical realities, offering insights for inspectors, installers and designers alike.

Water Heater Sizing: Balancing Draw and Recovery

The IPC does not mandate a specific method for sizing water heaters. Instead, it places the responsibility on the plumbing system designer to select equipment that meets the building’s operational demands.

For storage-type water heaters, two key performance metrics must be considered:

- Draw Capacity: The initial volume of hot water available before the temperature drops due to cold water mixing. For instance, a 50-gallon tank may yield only 40 gallons of usable hot water before the temperature falls below comfort levels.

- Recovery Rate: The rate at which the heater reheats incoming cold water, determined by the energy input (e.g., electric wattage or gas BTU/hr) and the temperature rise required.

Together, these metrics form the First Hour Rating (FHR), a standardized measure developed by the U.S. Department of Energy (DOE) to estimate performance during peak demand. For example, a 40-gallon electric unit with a 4,500-watt element might have an FHR of approximately 54 gallons:

- Draw: 40 × 0.85 = 34 gallons

- Recovery: ~20 gallons

- FHR = 34 + 20 = 54 gallons

While rules of thumb (e.g., a 50-gallon unit for a three-bedroom, two-bath home) are still common, the Energy Guide label provides standardized FHR data to support accurate sizing and model comparison.

Proper sizing ensures:

- Reliable hot water during peak use

- Energy efficiency by avoiding oversizing

- Fewer callbacks and greater user satisfaction

Designers should consult manufacturer specifications, DOE ratings, and building usage patterns to select appropriately sized units.

Location Requirements: Accessibility and Safety

IPC Section 501.4 mandates that water heaters be installed in locations that allow for observation, maintenance, service and replacement. Key considerations include:

- Minimum clearances for access

- 30″ x 30″ working space in front of the control side

- Prohibited locations, such as storage closets or bedrooms without sealed enclosures

- Elevation requirements in garages (typically 18″ above the floor for units with ignition sources, unless listed as Flammable Vapor Ignition Resistant)

Installers should also plan for future maintenance, especially in multi-family or commercial settings.

Energy Efficiency: Why Placement Matters

Water heater location significantly impacts energy use, heat loss and system longevity:

- Units in unconditioned spaces (e.g., garages, basements) lose heat more rapidly.

- Long pipe runs increase wait times and water waste.

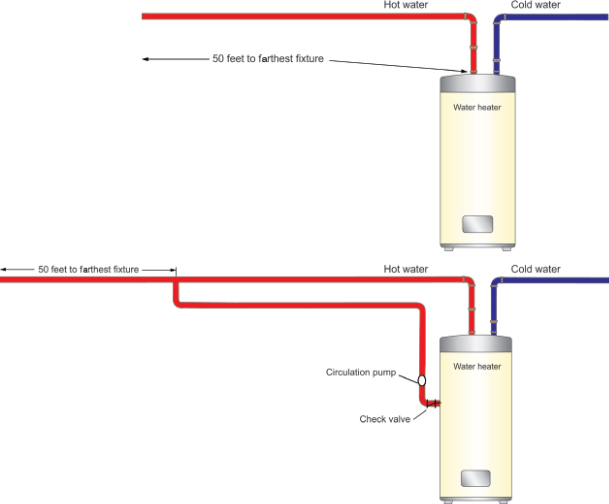

- The IPC limits hot and tempered water piping to 50 feet; the International Residential Code® (IRC®) allows 100 feet, while the International Energy Conservation Code® (IECC®) imposes stricter limits (as low as four feet for two-inch piping and larger).

Best practice: Install water heaters in conditioned, insulated spaces near high-demand fixtures to reduce energy use and improve performance.

Inspections: Common Pitfalls

Inspectors frequently encounter:

- Improper venting or vent materials

- Inadequate access clearance

- Oversized electrical breakers

- Missing sediment traps on gas lines

- Loose or missing seismic strapping

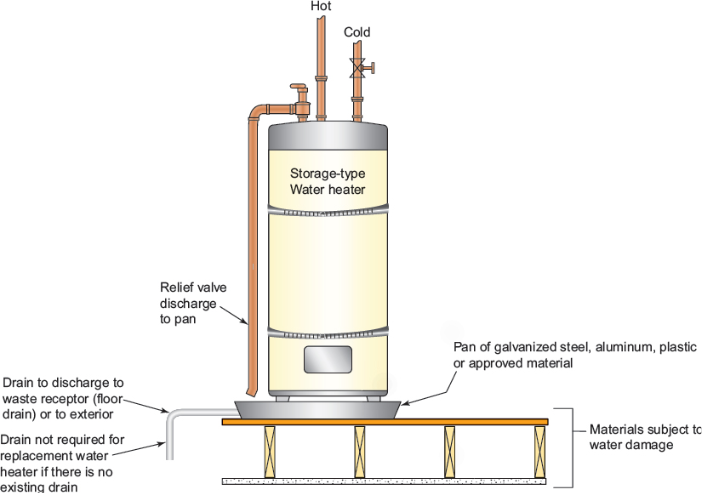

- Missing catch pans in damage-prone areas

- Incorrect catch pan drain terminations

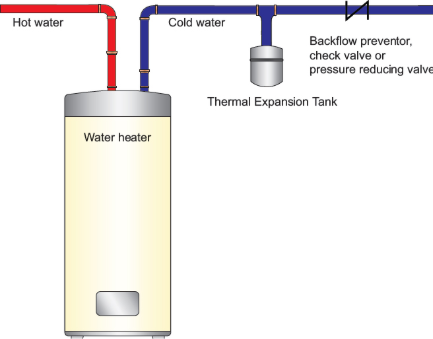

- Unsupported expansion tanks

- Improper or missing TPR discharge piping

Each of these issues reflects a failure to meet code requirements and can lead to hazardous conditions, reduced efficiency, failed inspections and costly remediation.

Code vs. Practicality: Bridging the Gap

While the IPC provides a solid framework, successful installations require thoughtful application:

- Designers must consider usage patterns, climate and layout.

- Installers should anticipate inspection criteria and future serviceability.

- Inspectors must balance code enforcement with practical feasibility.

Final Thoughts

Water heater sizing and placement are not just code checkboxes; they are foundational to the safety, efficiency and reliability of a building plumbing system. Proper sizing ensures consistent hot water delivery and energy savings, while strategic placement supports accessibility and long-term performance.

The IPC sets the standard, but it’s up to professionals to apply both technical expertise and practical judgment. By understanding draw capacity, recovery rate, location requirements and common inspection pitfalls, designers, installers and inspectors can work together to deliver systems that are not only code-compliant but also safe, efficient and built to last.

To access any of ICC’s PMG-related resources, click here. To subscribe to the PMG newsletter, click here.