Hydrogen Facilities: Laying the Groundwork for Safety Integration into the Built Environment

Informed code officials provide the first line of defense in protecting public safety, ensuring that hydrogen installations meet rigorous design and safety criteria while also enabling innovation.

Hydrogen is gaining renewed attention as a cornerstone of the evolving clean energy landscape. As an energy carrier, it offers remarkable versatility and potential across a broad spectrum of applications.

With a high energy density by weight, hydrogen can be efficiently converted into mechanical work or heat, making it an invaluable resource in supporting diverse energy and industrial processes. Perhaps most compelling is its environmental profile: when used in a fuel cell to provide energy, the only byproducts are water and heat—completely avoiding production of greenhouse gases.

Historically, hydrogen has been crucial in industries like petroleum refining, fertilizer manufacturing and glass production. Recently, its use has expanded to powering industrial forklifts and medium- to heavy-duty transportation such as buses, rail systems and long-haul trucks. In some regions, it is blended into natural gas pipelines for residential and power generation.

Hydrogen is currently being examined for various new applications, including:

- Maritime port operations, where it powers cargo-handling equipment

- Aviation, such as zero-emission aircraft and ground-support activities

- Stationary backup power systems

These uses underscore hydrogen’s role in the shift to a low-carbon future.

Maintaining Hydrogen Safety

Code officials play an important part in maintaining hydrogen safety. Permitting for hydrogen projects can be complex due to the unique properties of hydrogen. Like all fuels, hydrogen possesses inherent hazards; however, the repercussions of hydrogen-related incidents can be more severe.

Hazards

Owing to its low molecular weight, hydrogen can easily permeate materials that are not typically considered porous. Upon release, its high energy content can result in ignition events that are more intense than those associated with other common fuels.

Gaseous hydrogen storage pressures can exceed 12,000 psi, and in its liquid form, it is stored at cryogenic temperatures near –423°F. Hydrogen can cause embrittlement in various metals and deformation in certain polymers, which can lead to leaks in piping and other equipment. Furthermore, hydrogen can be ignited by energy sources 50 times smaller than a typical static electric charge, potentially leading to fires and explosions.

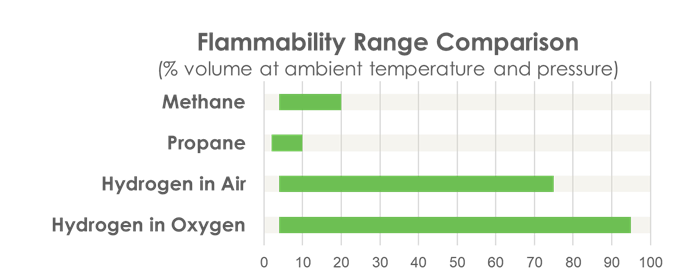

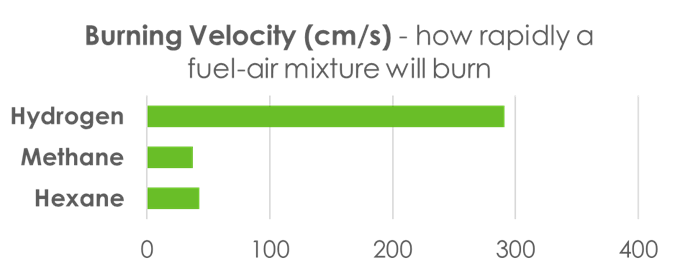

Hydrogen has a broad flammability range of four percent to 75 percent in the air. When ignited in its pure form, it burns with a pale blue, nearly invisible flame that emits minimal radiant heat, making detection challenging without thermal imaging cameras. Hydrogen also exhibits a high burning velocity, resulting in rapid combustion of hydrogen-air mixtures and increasing the potential for deflagrations and detonations, which produce damaging pressure waves.

Comparison to Common Fuels

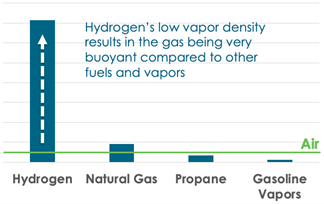

It is useful to compare the properties of hydrogen to other common fuels, depicted in the following graphs on flammability range, burning velocity and vapor density.

Hydrogen-Related Codes and Standards

Despite the previous discussion of hazards and properties, hydrogen has been used safely within the industry for a century. Mature safety knowledge and best practices exist. Bringing that knowledge to those not previously exposed to hydrogen is essential for its safe use. In short, hydrogen should not be feared, but respected.

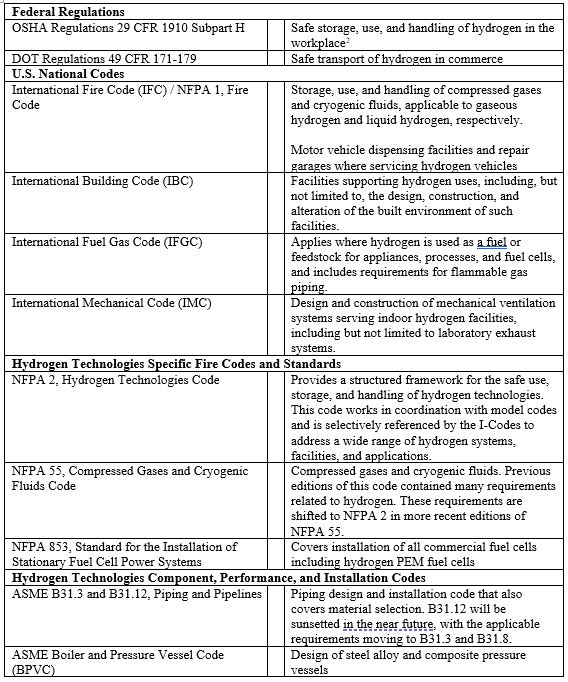

Significant efforts have been made over the past decade to develop and improve codes and standards to support the deployment and growth in hydrogen use and applications. The International Code Council provides requirements for the use of hydrogen primarily in the International Fire Code® (IFC) and the International Fuel Gas Code® (IFGC).

The IFC addresses hydrogen through generic requirements found in Chapter 53 (Compressed Gases) and 58 (Flammable Gases and Flammable Cryogenic Fluids), specific requirements for hydrogen fueling stations and repair garages in 2309 and 2311, and associated references to NFPA 2, Hydrogen Technologies Code. Chapter 7 of the IFGC provides extensive requirements for gaseous hydrogen systems.

The 2024 edition of the IFC brings additional focused requirements on this topic by directing hydrogen motor fuel-dispensing stations and repair garages to be designed, constructed and maintained in accordance with NFPA 2.

NFPA 2 is meant to be an all-encompassing document establishing requirements for hydrogen technologies. The first edition of NFPA 2 was released in 2011, and the 2023 edition is currently available for use.

The document was primarily developed from existing NFPA codes and standards (e.g., NFPA 52, Vehicular Gaseous Fuel Systems Code; NFPA 55, Compressed Gases and Cryogenic Fluids Code; and NFPA 853, Standard for the Installation of Stationary Fuel Cell Power Systems) and is meant to provide users with a single resource to support the design and approval of hydrogen equipment and facilities.

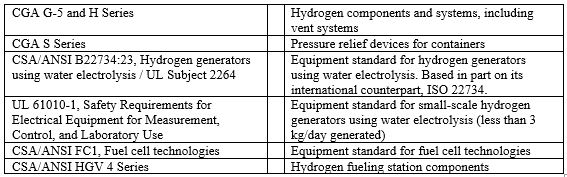

Many existing codes and standards establish the requirements for hydrogen systems. The table below outlines some of the most widely recognized and applicable standards in the United States.

As hydrogen technologies expand into various applications, code development often lags behind the issues that arise from the technology’s rapid changes and deployment. Furthermore, the practices used during the technology development phase do not always translate to code-compliant configurations for commercial deployment. This can lead to permitting challenges and the need for alternative means and methods (AM&M).

When implemented, AM&Ms should be formally justified and demonstrate that the facility or equipment is suitable for their intended purpose and meets safety requirements.

Basic Design Considerations for Hydrogen Facilities

Hydrogen systems pose challenges due to the gas’s unique properties. Therefore, safety features and design elements must be carefully planned and implemented. The following topics are especially critical for hydrogen facilities:

Sitting and Separation Distances

Ensuring adequate clearance is essential for reducing risks to people and property in the event of a release or ignition, and it also facilitates safe emergency access. As hydrogen usage increases, there is a growing demand for facilities in densely populated urban areas.

This creates a conflict between usability, regulatory requirements and safety considerations, which can challenge the approval process. Consequently, many sites have sought approval for alternative solutions that deviate from the prescriptive requirements of the IFC and NFPA 2.

Ventilation

Ventilation is crucial in minimizing the risk of flammable gas accumulation. In outdoor environments, hydrogen can be diluted effectively by avoiding overhead structures that trap gas, allowing it to disperse naturally.

For indoor settings, mechanical ventilation should be designed to maintain hydrogen concentrations below the lower flammable limit by exhausting air at high points—where hydrogen can accumulate—and supplying fresh air at low levels to create a thorough airflow across the enclosure or room. However, it is important to note that no practical indoor ventilation system can quickly dilute a massive release from a pressurized vessel, pipe rupture or blowdown.

Nonetheless, it will help reduce the size of the flammable cloud and the duration of risk. In spaces where heavier-than-air flammable gases or vapors are also present, both low and high exhausts may be necessary.

Leak Detection

Hydrogen facilities frequently utilize combustible gas detectors and flame detectors, and advancements in sensor technology are progressing rapidly. Detection strategies should be customized to the specific application and must encompass proper sensor placement (validated to ensure avoidance of trapped locations and enable timely exhaust), detection thresholds and notification methods to ensure prompt response.

Electrical Equipment Classification

Electrical equipment located in close proximity to hydrogen systems must be appropriately rated to prevent it from becoming a potential ignition source. In the United States, such equipment should be suitable for installation within Class I, Group B environments as specified by NFPA 70. Alternative methods to classify electrical equipment may include purged or pressurized enclosures, among others. The appropriate use, arrangement, and reliability of these alternative approaches are subject to the approval of the authorities having jurisdiction (AHJ).

Emergency Shutdown Systems (ESS)

Effective isolation is essential for controlling and terminating hydrogen releases as hydrogen fires cannot be effectively extinguished without removing the fuel source. ESS should be designed to activate in response to detection alarms, fire alarms, ventilation loss or manual activation via emergency shutdown devices (ESDs). Upon activation, the ESS should de-energize unclassified electrical components, close all automatic shutoff control valves, and coordinate with other safety systems such as fire alarms.

ESDs should be strategically located both on hydrogen equipment and at a remote location at least 25 feet away to allow safe access during an emergency. The ESS should also provide a means for isolating bulk storage from downstream or upstream systems.

Material Compatibility

Hydrogen can lead to embrittlement in certain metals, which may result in cracks, leaks and system failures. Exposure to hydrogen can also deform some polymers, causing leaks in gaskets and other locations. Generally, austenitic stainless steels, copper and copper alloys are recommended for metals. Nickel and most nickel alloys, as well as gray, ductile and malleable cast irons, are typically avoided.

However, there is no universal rule for using metals with hydrogen. The suitability of materials depends on pressure, temperature and service conditions, and some of the mentioned materials could be suitable in low-pressure applications.

Hazard Analysis

Every hydrogen project, irrespective of its scale, must undergo a comprehensive hazard analysis. This assessment should be conducted by the project team to quantify the potential consequences and likelihood of release, ignition, and escalation. The type and depth of the assessment—whether qualitative hazard reviews or quantitative risk assessments—should correspond to the complexity and risk profile of the specific application. The assumptions and results of the analysis must be provided to the permitting authority. Any deviations from the design used for the hazard assessment and commissioning of the facility should be carefully evaluated against the original assessment to ensure that the facility maintains the safety standards initially approved.

This article provides a brief overview of a few important considerations. As the figure below reveals, there is much more to consider.

Hydrogen Fuel Resources

Despite the challenges, there are many online and training resources available to help code officials, project proponents and first responders as they prepare for the arrival of this new technology.

A few highlighted examples include:

Permitting Resources

- International Code Council’s Hot Topics – Hydrogen Fuel – Provides information on ICC’s hydrogen resources.

- org – A resource from the U.S. Department of Energy and Pacific Northwest National Laboratory offering data, incident lessons learned, technical references, and safety planning tools.

- Permitting Hydrogen Fueling Station – Four-Part Video Series – This free video series, available on H2Tools.org, gives AHJs and other interested parties a quick orientation in permitting hydrogen fueling stations.

- NFPA 2 Plan Review Checklist and National Permit Guide for Hydrogen Fueling Stations – The Hydrogen Fueling Station Plan Review Checklist (the Checklist) assists users in demonstrating compliance with NFPA 2, 2016 Edition. The Checklist simplifies both the project development and safety review processes.

Expert Review

The Hydrogen Safety Panel (HSP) is familiar with safety considerations for new technology. Established in 2003, the panel supports the U.S. Department of Energy’s commercialization of fuel cell technologies. The panel consists of 25 members with expertise from commercial, industrial, government and academic sectors. The panel’s activities include reviewing equipment and facility designs, assessing risks and safety plans, and conducting site safety reviews.

To date, the HSP has conducted over 700 project review activities, developed more than 250 FAQs, created 16 safety guidelines, and established over 100 best safety practices. The HSP can address technical questions. They can be contacted by email at hsp@h2tools.org.

Design and Safety Guidance

- NREL Hydrogen Technologies Safety Guide – Offers practical recommendations on risk mitigation, leak detection, and emergency response.

- Hydrogen Safety Panel’s Hydrogen Equipment Certification Guide – Assists code officials, designers, owners, evaluators, and others with the application of the listing and approval requirements pertinent to the design and/or installation of hydrogen equipment as regulated by the model codes.

Helpful Additions to Your Training Toolkit

- Center for Hydrogen Safety (CHS) – Provides training, webinars, and technical support for hydrogen safety professionals.

- Hydrogen Safety Panel – Offers contracted expert reviews of hydrogen installations and emerging safety issues.

- DOE’s Code Official Training Course – Though updated in 2016, this course can be a useful resource with end-of-module questions to reinforce key concepts.

- CHS’s First Responder Micro Training – This four-part multimedia course aims to better inform incident responders and support the safe handling and use of hydrogen in a variety of fuel cell applications.

As hydrogen continues to emerge as a critical component of the clean energy transition, code officials are uniquely positioned to ensure its safe and responsible integration into the built environment. Understanding hydrogen’s properties, hazards and applicable codes and standards is not just beneficial—it is essential.

Informed code officials provide the first line of defense in protecting public safety, ensuring that installations meet rigorous design and safety criteria while also enabling innovation. By actively seeking knowledge, participating in training and leveraging available resources, officials can confidently evaluate hydrogen projects, promote best practices and contribute meaningfully to a safer, more sustainable energy future.

Future articles will further explore key topics such as sitting considerations, permitting case studies and the evolving framework for certifications and approvals. We encourage you to stay connected to gain more insights into practical guidance and permitting strategies for hydrogen facilities.

To learn more about hydrogen fuel, click here.