Batteries & Energy Storage Systems (ESS)

Lithium-ion batteries are rechargeable batteries known for their lightweight and long-lasting properties. They can be found in electric vehicles and battery energy storage systems (ESS), as well as smaller devices including e-bikes, e-scooters, cell phones, computers and hoverboards. Despite their wide range of uses in commercial and residential settings, these technologies present unique safety challenges.

New innovations and battery chemistries continue to be developed, challenging manufacturers, code officials and consumers to stay up-to-date on operational best practices of the technology.

Learn how codes, standards and guidelines are adapting to support the safe use, manufacture, storage, use and recycling of batteries and ESS, and find key resources to help ensure protection for installers, code officials, system designers, retailers and everyday users.

Battery and ESS Basics: What You Need to Know

From personal electronics to mobility devices, the consumer demand for reliable stored energy is drastically increasing. These needs are further increased by the desire for more clean energy in the automotive sector as well as the growing demand for improvements to our utility systems and the need for more stored energy.

As the development, manufacture and use of these batteries increases, attention to the storage, handling, disposal and recycling of new and aged battery units is crucial to ensure health and safety in the built environment and develop future code considerations that address battery chemistries and technologies.

To ensure performance, longevity and safety, it’s critical to follow best practices throughout the lifecycle of lithium-ion batteries and ESS.

Batteries in Emergency Planning and Response

Many U.S. states and other countries have experienced a significant surge in fires associated with lithium-ion batteries.

The use of lithium-ion batteries as ESS in our homes can create a potential need for early identification in post incident mitigation and evaluation. Containment, collection and disposal of batteries impacted by a disaster, especially involving fire or flood, takes much care and consideration as part of the response and recovery phases of disaster management.

Training emergency responders and managers to stay up to date in codes, regulations and best practices of battery handling is critical to maintain community awareness and safety. This is especially crucial after a disaster when damaged batteries are left in homes and buildings affected by the disaster.

The Code Council’s When Disaster Strikes (WDS) Institute prepares participants to properly evaluate damage through instruction, interactive activities and review of case studies. The goals of the WDS Institute are to increase the number of trained and qualified Post-Disaster Building Safety Evaluators and Post-Disaster Building Safety Evaluation Coordinators and to increase awareness regarding when and how to perform Post-Disaster Building Safety Evaluations. Learn more here.

Codes and Standards

Adopting and implementing current building codes and standards ensures that lithium-ion batteries and ESS are installed, operated and maintained safely to minimize risks of fire, electrical hazards and system failures.

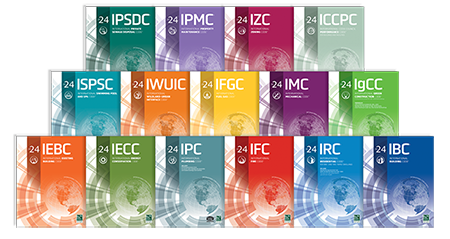

The International Code Council (ICC), through its membership, code action committees and the code development process, has rapidly developed the I-Codes since the 2015 editions of the International Fire Code® (IFC), International Building Code® (IBC) and International Residential Code® (IRC) to incorporate the evolving and advancing battery chemistries and technologies. These codes and standards incorporate the latest research and best practices, helping protect both occupants and first responders while supporting the safe integration of advanced energy technologies.

Over the past two code development cycles, the collaborative efforts of ICC Code Action Committees and various Code Development Committees have established and enhanced a minimum level of battery safety across the built environment.

This progress is evident in the 2024 suite of I-Codes including the IFC, IBC and IRC as shown in the ESS Development Time frame recap below.

2000-2015

Early Considerations for Battery Storage and Fire Safety

2018

IBC/IFC: Initial Recognition of Lithium-Ion and Emerging Technologies

2018

IBC/IFC: Expansion of Fire Protection Requirements for Energy Storage

2021

IBC/IFC/IRC: Refining ESS Regulations and Integration of Large-Scale Systems

2024

IBC/IFC/IRC: A Comprehensive Framework for ESS in the Built Environment

Resources

The ICC Ad-Hoc Battery and Energy Storage Committee's efforts are documented in this comprehensive report that includes how and where batteries and ESS are used in the built environment, details the committee's code gap analysis approach, highlights areas of focus within future I-Codes, examines professional training and community education needs, and explains necessary public awareness strategies for maintenance and charging of personal mobility devices.